How Does RFID Work for Vehicle Gate Entry?

An RFID tag, or radio frequency identification tag, is something you might find in everything from wrist bands at amusement parks to identification tags in secure location. It can be used to mark objects that might require tracking or locating in some way. RFID offers a fantastic way to control such objects as vehicle gate…

How Does RFID Work for Vehicle Gate Entry?

How Does RFID Work for Vehicle Gate Entry?

An RFID tag, or radio frequency identification tag, is something you might find in everything from wrist bands at amusement parks to identification tags in secure location. It can be used to mark objects that might require tracking or locating in some way. RFID offers a fantastic way to control such objects as vehicle gate entry systems, too. It is the sort of nimble and flexible solution ideal for vehicle access control at a residential location as well as a commercial or industrial setting.

How would an RFID tag work within a vehicle gate entry system?

A good way to answer that question is to begin with a clear understanding of just how RFID operates at the most basic level.

RFID Tags 101

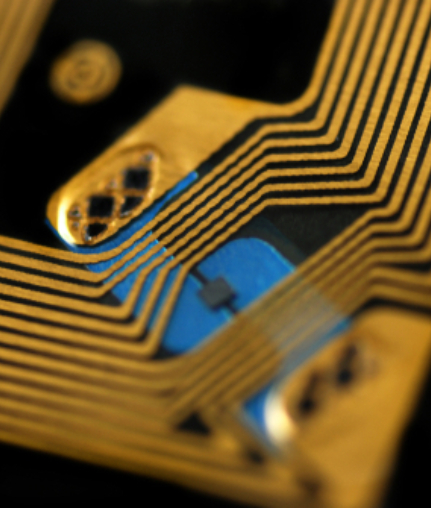

An RFID tag contains technology that allows it to support tracking, and it accesses radio frequency waves in order to do so. At the most basic level, it is a technology that features two parts. One is a “transmitter” and the other is a receiver. The tag contains the receiver, which is often described as an integrated circuit or chip. This chip stores the information that the tag is used to contain.

For example, the tag may have been placed on a vehicle, and it contains such information as the vehicle’s make and unique ID or it may even contain user information, such as employee or residential data. It may allow the user to also enter the gate, opening the vehicle gate entry.

And this is where we can start to see just how vehicle access control and an RFID tag system are a match made in heaven.

Your Vehicle Gate Entry Will Benefit from RFID Vehicle Access Control

A singular challenge in modern security is controlling access to a facility (whether industrial or residential), while upholding the level of protection required. The traditional solution is a gated entry or security gate built in the center of a security fence or other structure. While it is always possible to have human-powered security gates with guards who check and clear those seeking entry and allow or deny access, it is not cost efficient or easily managed. It is an outdated system in the face of an RFID tag and vehicle access control system.

Why? There is the risk of human error and fraud that can allow someone to gain entry when they have no reason or right to do so. Just consider that guards or sentries at gates have everything from paper lists of names and approved users, to simply being flustered by someone who insists on going through.

The same can be said of the flaws and challenges of things like “clickers” or remote control devices that can come up with an untold number of glitches. From dead batteries to outdated systems that can allow security codes to be stolen right out of the air, there are too many risks inherent in hand-held devices meant to communicate with most radio frequency systems.

Lastly, there are frequently delays between the cuing of a system and its actual operation. For example, a traditional gate that lifts and lowers has that pause that can take a count of five or ten before it kicks back into action. When there are four or more vehicles at such a vehicle gate entry, the delays can be excessive. There are always going to be traffic issues associated with the manual vehicle gate entry and vehicle access control systems, too. Just visit any industrial, commercial or residential facility during peak commuter hours and you’ll see how this sort of access control can prove problematic. It can even cause street traffic issues.

So, there are many challenges, including the expenses of maintaining round the clock staff that can operate at optimal levels. There are also the infrastructure expenses of investing in devices that have to be installed and maintained, and then used properly by those who require access through a vehicle gate entry.

And once you discover RFID tag technologies, and the fact that they can be integrated into a vehicle access control system and paired to a vehicle gate entry, you can see how they might be a premium or optimized approach to security and control.

How RFID Works With Vehicles

While it will always be necessary to pair any RFID tag system with preferred software and technologies that allow the user to make the most of it, the simplest truth is that vehicles can be fitted with affordable tags that will convey the data needed.

As a simple illustration, Express offers those in need of vehicle access control at a vehicle gate entry such solutions as RFID tags in:

- Key fobs – Residents or employees and vendors can slip a tag on to their car key fob and the technology will interact with the fob every time the car nears the gate.

- Rearview mirror hang tags – Residents and employees or vendors can just hang the tag on the mirror and let it work as far away as 25 feet from the gate, maximizing the speed of the system

- Windshield tags – Residents and employees can be issued tags that stick right to the windscreen of any vehicle, and it too might allow them to access the vehicle gate entry or vehicle access control system from up to 20 feet or more

A system for vehicle access control can use the two parts to an RFID tag system. It can have the antenna that waits for any messages from the tags to reach the proximity zone. The passive, vehicle-mounted fob, hang tag or windshield tag can send out little more than a number assigned to it. This can be used to match it against a data set of vehicle tags allowed to pass through the entry. In seconds, the data can be exchanged, the vehicle gate entry opened, and the community or facility kept secure.

There are many moving parts in modern security, but an RFID tag can really streamline things and protect security to the greatest and most user-friendly degree possible.