Process Control Labels

Express delivers Custom Industrial Control Tags with the fastest turn-around time in the industry.

Request a quote and receive a response within one business day. Or let us know if you have questions and our specialists based in the U.S. will work with you to provide an accurate quote for the most appropriate product for your requirement.

Whether you have an engineered drawing or you want us to design from scratch our Graphics team will produce a product proof for your review before production begins.

Metal tags that endure and perform in even the harshest environments.

Quality barcodes that conform to industry standards and deliver excellent read rates.

Industrial Process Control Labels for Optimized Identification

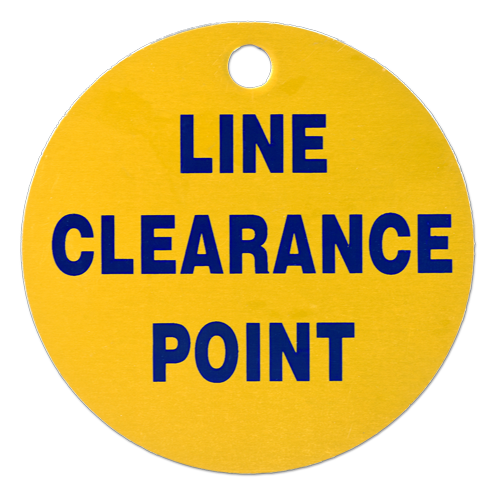

Enhance operational efficiency with high-quality industrial process control labels tailored for demanding environments. These labels and tags are engineered to support identification across chemical processes, SCADA systems, and essential process control equipment. Your options include durable barcoded labels, machine identification tags, and chemical-resistant solutions to withstand harsh conditions. Express Industrial Control Labels are perfect for labeling pipes, valves, and safety points to improve traceability and simplify maintenance.

Reduce labor and errors with accurate data collection at valves and other key points

Industrial Process Control Labels are engineered for excellent readability and durable design to withstands the demands of the harshest environments and deliver outstanding performance for years. Available with an optional Teflon™ coating that provides a label surface that sheds paint, acids, strong caustics and other chemicals.

Process Control Label customization.

Tags are built to meet your specific needs with numerous options to choose from including:

- Special Data Requirements

- Tag Size and Shape

- Material Type (Aluminum or Steel)

- Material Thickness

- Teflon™ Coating if Desired

- Color Coding

- Custom Text

- Hole Count and Location

Barcode Identification

Express Valve tags are printed with the barcode symbology of your choice Code 39, QR Code, QR Code, Code 128, or other barcode symbologies to seamlessly integrate into any compliance or barcode scanning system. Barcoded valve tags enable field technicians to reliably and accurately inspect leaks, capture data, and perform preventative maintenance throughout the field.

Quality Industrial Control Tags

Express only uses premium materials and proven production processes to guarantee maximum tag performance and durability. Anodized aluminum and stainless steel valve tags are custom-designed and manufactured to guarantee decades of resistance and withstand repeated abrasion, salt spray, extended UV exposure, extreme heat, multiple freeze-thaw cycles, and caustic chemicals. Express uses photosensitive aluminum, which seals the barcode and text beneath the surface of the aluminum for extra durability. Anodized aluminum valve tags are manufactured out of photosensitive aluminum, which seals the barcode and text images beneath the aluminum surface for extra durability. Corrosion-resistant stainless steel valve tags are laser-marked or chemically-etched to provide the ultimate resistance to caustic chemicals and solvents. Teflon™ and coatings are available on all valve tags for added resistance to paint, oil, and grease. With either option, Express tags provide decades of service in the harshest oil, gas, and petrochemical environments.

Industry Resources

Your LDAR program should schedule inspections to ensure compliance, track work orders as soon as leaks are detected, and report such leaks to the appropriate environmental agency. These best practices are streamlined with the use of automatic data capture technology, such as barcode labels and tags.

- Leak Detection and Repair: A Best Practices Guide

- Air Emission Measurement Center (EMC) Test Methods

- Method 21: Volatile Organic Compound Leaks

- Inspection Manual: Federal Equipment Leak Regulations for the Chemical Manufacturing Industry

- EPA Compliance Monitoring Programs

- EPA Greenhouse Gas Reporting Program (GHGRP) – Subpart W – Petroleum and Natural Gas Systems

- EPA Compliance Monitoring Programs

- Express Company Profile

- Aluminum Sub-Surface (Photographic) Imaged Anodized Aluminum

- Stainless Steel Laser Marked